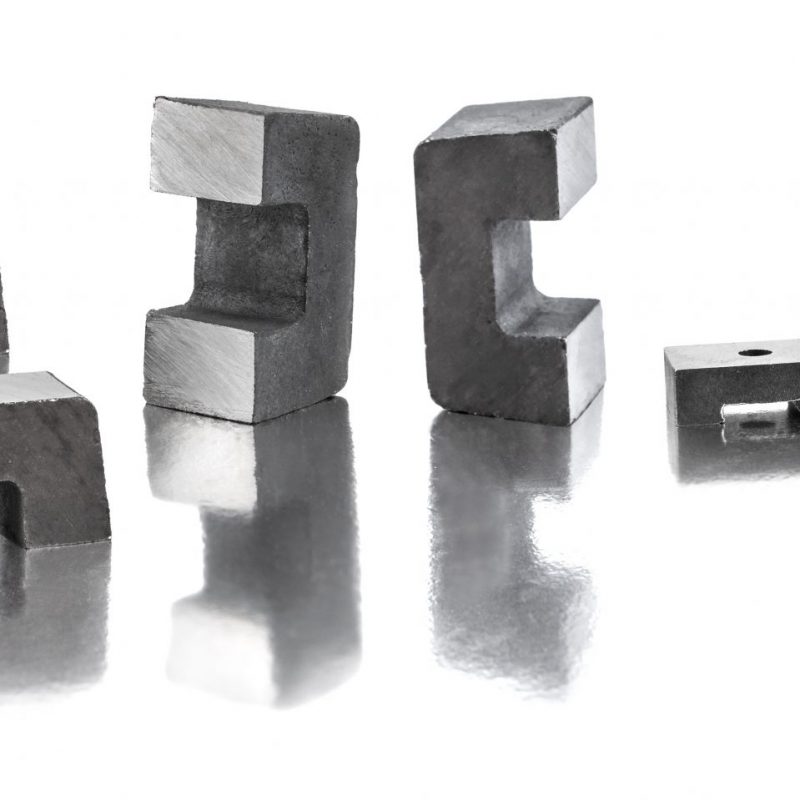

Samarium-Cobalt

A samarium-cobalt magnet is a type of permanent magnet made of an alloy of samarium and cobalt. They are light grey in colour and have a density of 8.2. Samarium Cobalt magnets have a very high magnetic energy (BHmax).

Read descriptionSamarium-Cobalt range

Rare earth alloys first appeared in the field of permanent magnets in the 1970s. The two main characteristics that led to the interest in these alloys were their high energy density (BHmax) and their superior demagnetisation resistance (HcB and HcJ).

The binary samarium-cobalt compounds used in industry are SmCo5 and Sm2Co17.

Two processes are used to obtain these compounds: one consisting of a two-stage co-reduction of the oxide mixtures followed by vacuum melting, and the other consisting of a direct vacuum melting of the samarium and cobalt. The alloy obtained by either process is then ground into powder, pressed under a magnetic field and sintered at about 1100°C in an induction furnace. As samarium powder is extremely reactive in ambient air, sintering must be carried out in an inert atmosphere or under vacuum.

The main advantage of the magnetic properties of samarium-cobalt magnets is that they are very stable in temperature, allowing them to be used at temperatures up to 300°C.

Samarium-cobalt magnets are uncoated and have good corrosion resistance. Be careful not to use them in the presence of hydrogen or chlorine.

Finally, samarium-cobalt magnets are particularly fragile magnets with very poor mechanical properties; they are therefore easily chipped, without any impact on the magnetic properties of the finished magnet. However, they should be handled with the utmost care.

HOLDING FORCE

- Magnetic force is optimal when magnet is in contact with a mild steel frame, flat, clean and rather thick. It is lower with allied steels and cast iron (less 30% for cast iron).

- It is lower in the presence of an air gap (space between the part to magnetize and the polar face of the magnet).

- It is decreasing by 0.08% every degree C (see besides curve). This loss is reversible.

INDUCTION ON SURFACE

- The maximum value of induction in surface at 20°C is about 4000 Gauss for SmCo flat pot magnets and magnetic blocks.

- This value is decreasing by 0.04% every degree C when temperature is increasing. It is a reversible loss.

MECHANICAL RESISTANCE

- These ceramics are very fragile. They must be handled carefully.

RESISTANCE TO CHEMICALS

- Samaryum Cobalt magnets must not be put in the proximity of hydrogen and chlorine.